There is exciting news for those in the adhesives industry: budding researchers from Michigan State University are exploring the idea of an adhesive that bonds composite and non-composite materials but can be pulled apart when necessary. This exciting research could result in a groundbreaking product for the adhesives industry and answer an age-old problem for manufacturers in a range of sectors.

The team behind the project is located within Michigan State University’s Composite Vehicle Research Center. Much of the work is being funded by a combination of the US Department of Energy and the American Chemistry Council.

The problem

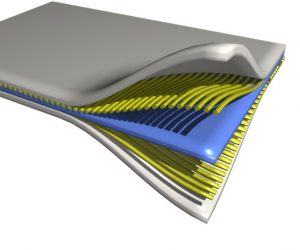

The car industry in the US has a federal mandate to manufacture cars that return 54.5 miles to the gallon by the year 2025. For this to be achieved, cars will need to be much lighter and the industry will need to start using composite materials; however, bonding these with traditional metals will be the tricky part.

The team is looking for a way to join composite and non-composite materials in a way that does not compromise the existing structure and properties. Traditional ways of bonding include drilling holes, which severely compromises the composite, or using an adhesive as the bond, which is then hard to reverse. Products such as metal bonding adhesive from companies such as http://www.ct1ltd.com/en are absolutely essential to many industries; however, there is also the need for an adhesive with a bond that can be broken.

The solution

The team is looking into creating a product that can be easily repaired, healed or taken apart while also creating a strong bond when in use. This will involve the use of special properties in the form of electrically conductive nanoparticles, which will be added to the adhesive. These particles will be activated with electromagnetic radiation, causing them to vibrate, adding heat to the adhesive. The full story with technical details can be found in the Michigan State University magazine MSU Today.

Another key challenge is to create a product that does not dramatically alter the factory line. With the automotive industry in mind for this product, the team needs to ensure that its introduction will not require full-scale changes to the line.

The team hopes to announce more about its important research in the near future.